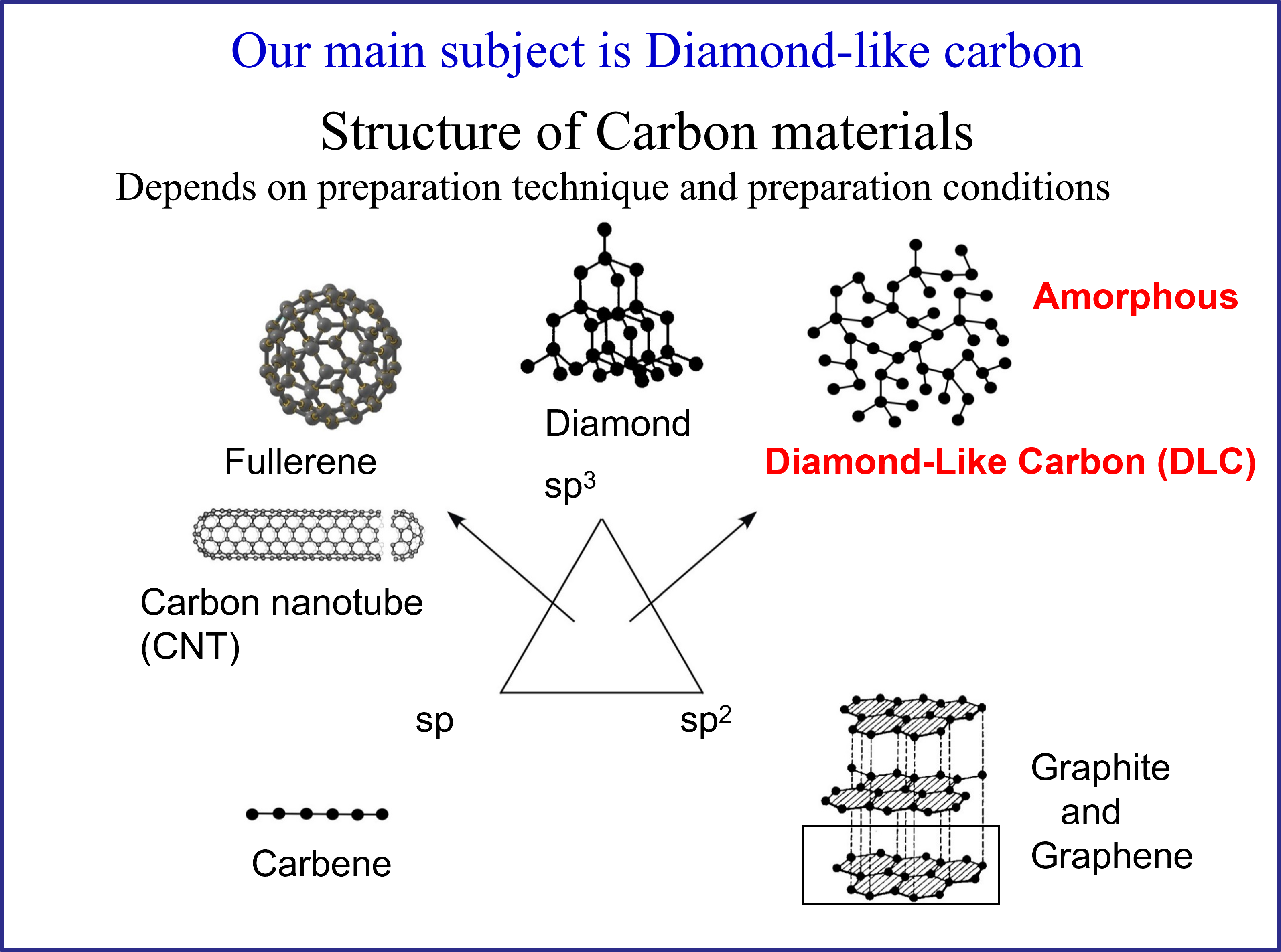

The DLC coating process employs a plasma-enhanced chemical vapor deposition (CVD) method combined with ion implantation. As illustrated in the figure on the left, a negative high-voltage pulse is applied to the substrate, which accelerates and attracts positive ions generated in the plasma through a prescribed method. These ions are then implanted into the substrate surface.

This technique enables both ion implantation into the substrate and the formation of a highly adherent DLC coating. One of its key advantages is the ability to process large areas, three-dimensional objects, and multiple components simultaneously, making it suitable for a wide range of industrial applications.

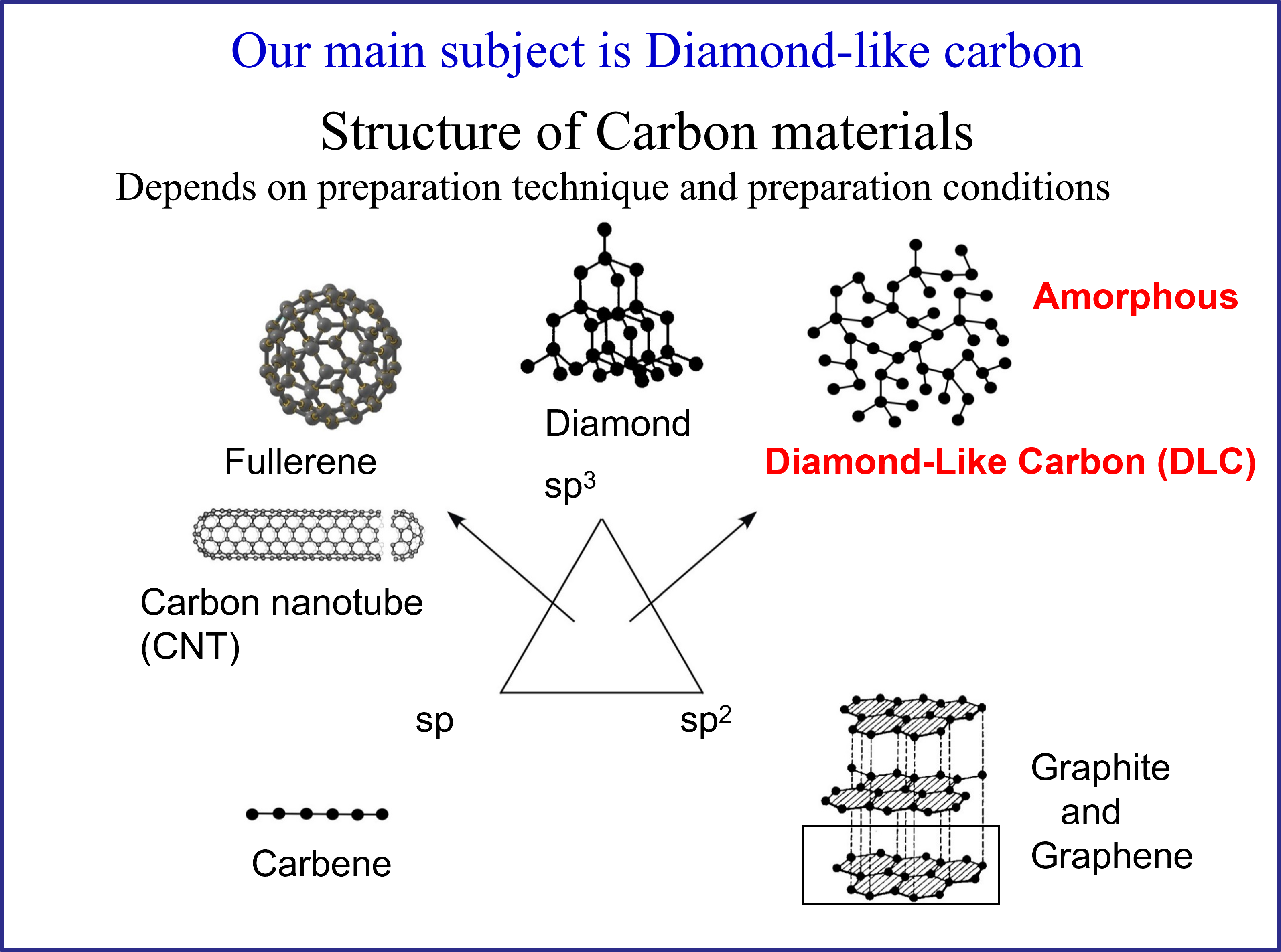

Diamond-like Carbon (DLC) is a carbon-based material with hardness comparable to that of diamond. When formed into a thin film, it is referred to as a DLC coating, which has a wide range of industrial applications.

At DLC Research Institute, our operations are based on the DLC coating technology developed by our representative during his tenure at the Nagasaki Prefectural Institute of Industrial Technology and the Graduate School of Engineering at Nagasaki University. This technology utilizes plasma source ion implantation. We provide technical development, consulting, and contract-based services related to surface treatment and materials engineering.

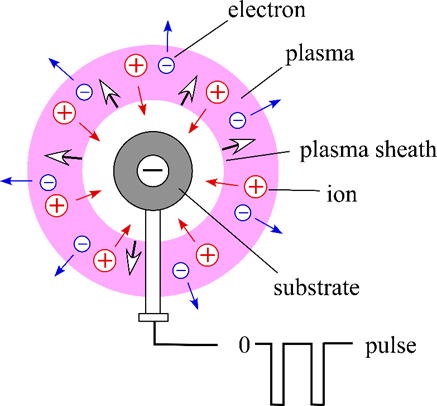

Scanning Probe Microscopy Image of DLC Film Deposited on a Silicon Wafer The surface exhibits exceptional smoothness, with a measured roughness

of Ra = 0.15 nm.

Home|

About | Services | Technical Info | Publications | Contact

Technical informations